Wartung von Sturmey-Archer Vier-, Fünf- und Sieben-Gang-Naben

Sturmey-Archer hat viele Vier- und Fünf-Gang Modelle über die Jahrzehnte entwickelt. Ein weiterer Artikel auf dieser Seite behandelt Aspekte, die allen Sturmey-Archer Modellen gemeinsamn sind. Besonders interessant dürften dabei folgende Abschnitte sein:

- Züge ersetzen

- Zugeinstellung

- Einstellen der Konen

- Sicherungsscheiben

- Achsenlängen

- Schmierung

Es gibt weitere Artikel, die folgende Theman abdecken:

- Alles über Nabenschaltungen

- Sturmey-Archer Naben

- Demontage von Sturmey-Archer Naben

- Wartung der Sturmey-Archer Dynohub und AG Nabe

- Verwendung und Wartung von Sturmey-Archer Schaltungsnaben

- Sturmey-Archer Teile und Namen

- Modell und Produktionsjahrbestimmung von Sturmey-Archer Nabenschaltungen

Getriebe

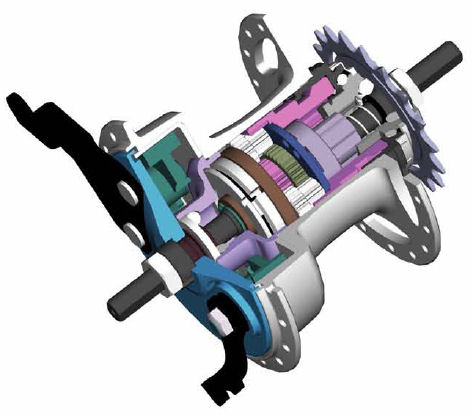

Außer bei ab 2015 neuen Vier-Gang-Naben, über die noch keine Informationen vorliegen, kann man feststellen, dass alle Vier-, Fünf- und Sieben-Gang-Naben einen ähnlichen Aufbau mit abgestuften Planetengetriebe haben. Sie haben zwei oder drei Sonnenräder, von dene jeweils immer nur eines zur gleichen Zeit mit der Achse verbunden ist. Die nebeneinanderliegenden Planetengetriebe sind aus einem Stück Metall (gefräst(, abgestuft mit zwei oder drei Übersetzungen verschiedener Größe. Durch die Einteiligkeit bewegen sie sich alle gleichzeitig. Das breite Ende des Planetengetriebes verzahnt sich mit einem der kleineren Sonnenräder und das schmale Ende verzahnt sich mit einem anderes (Mittelsektion bei Sieben-Gang-Naben) größeres Sonnenrad und dem Hohlrad. Diese Naben haben die direkte Übersetzung (1:1) im mittleren Gang und es gibt die Wahl zwischen mittlerer und großer Übersetzungsbandbreite je nachdem, welche Sonnenräder mit der Achse verbunden sind.

Diese Naben (zumindest die älteren Versionen) haben eine "neutrale" Position, wenn die Sonnenräder geschaltet werden, weil die Verankerung zweier Sonnenräder mit der Achse würde die Naben sofort blockieren. Eine träge oder ungenaue Zugeinstellung kann dazu führen, dass die Nabe beim Vorwärtspedalieren freiläuft oder schwammig schaltet. Ältere Naben haben den "neutraln" Gang zwischen der direkten Übersetzung und dem höchsten Gang. Wie man das richtige Ritzel und die Übersetzungen richtig wählt, wird auf einer weiteren Seite detaillierter erläutert.

- Siehe auch

Aktuelle Vier-Gang-Naben

Sturmey-Archer hat 2015 eine ganze Serie von Vier-Gang-Naben eingeführt. Diese Naben sind (zumindest in den USA) nicht sehr verbrteitet.

- Siehe auch

Übersetzungen für diese Naben sehen wie folgt aus:

| Übersetzung | 1,000 | 1,280 | 1,640 | 2,100 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sprung | 25% | 28% | 28% | |||||||||

Da der kleinste Gang hat eine 1:1 Übersetzung ist, sind sie insbesondere geeignet für Fahrräder mit kleinen Laufrädern. Diese Vier-Gang-Naben haben die verbreiteten Ritzel mit drei Nuten.

In der unten stehenden Tabelle sind technische Informationen der jeweiligen Naben verlinkt, die von der Sturmey-Archer Webseite, aus Katalogen stammen oder einer Websuche entspringen. Grün hinterlegte Zeilen deuten auf Modelle aus dem 2015er Katalog hin.

| Modell | Eigenschaften | Dokumentation |

|---|---|---|

X-RC4 |

Rücktrittbremse | Spezifikation |

X-RD4 |

Trommelbremse | Spezifikation |

X-RF4 |

keine Bremse | Spezifikation |

X-RK4 |

Scheibenbremse | Spezifikation |

Fünf-Gang-Naben

Sturmey Archer hat zum Ende das Jahres 2013 eine Serien von Fünf-Gang-Naben mit Rotationsschaltung eingeführt. Deren Übersetzungsbandbreite beträgt 244%.

- Siehe auch

Übersetzungen für diese Naben sehen wie folgt aus:

| Übersetzung | 0,640 | 0,800 | 1,000 | 1,250 | 1,563 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sprung | 25% | 25% | 25% | 25% | |||||||||||

- Beachte

Die Rotataionsschaltungsnaben mit fünf Gängen haben Ritzel mit sechs Nutzen und einer 50 mm Öffnung. Das sind nicht die gleichen wie sie bei anderen Naben eingesetzt werden.

- Siehe auch

Ältere Fünf-Gang-Naben

Die Vorgängerversionen der aktuellen Fünf-Gang-Naben, deren Modellbezeichnungen mit "(W)" für "wide" enden, haben die gewöhnlichen Ritzel mit drei Nuten, werden mit einer Schaltkette geschaltet und haben eine breitere Übersetzungsbandbreite.

Sturmey-Archer's previous 5-speed hubs, with model names ending in (W) for "wide", use the common 3-lug sprocket, shift with a pullchain and have a wider range, as follows:

| Übersetzung | 0,625 | 0,750 | 1,000 | 1,333 | 1,600 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sprung | 20% | 33,3% | 33,3% | 20% | |||||||||||

Die Spreizung zwischen den drei mittleren Gängen der (W) Naben sind die gleichen wie bei Sturmey-Archer Drei-Gang-Naben. Die äußeren Abstufungen sind geringer als die inneren. Das ist gewünscht, damit die Stufe vom vierten in den fünften Gang nicht so stark ist. Aber es reduziert die Abstufung zum unteren Ende hin, was wiederum ein nicht gewünschter Effekt ist.

Die SL-S50 Schalthebel für die (W) Naben (schwarze Blende) können überschalten, wemn herunterschaltet und die Nabe bleibt zwischen zwei Gängen hängen. Das erhöhten den Verschleiß, der sich im Durchrutschen im zweiten und vierten Gang bemerkbar macht. Die neueren Versionen mit einem Punkt auf der Blende haben weniger Flankenschlag. Der Gangselektionsmechanismus im Inneren kann verschleißen, was auch wieder zu Schaltproblemen führen kann. Der Schraibe, die den Federmechanismus hält, sollte mit Schraubenkleber gesichert werden, damit sie sich nicht selbständig herausschraubt.

In der unten stehenden Tabelle sind technische Informationen der jeweiligen Naben verlinkt, die von der Sturmey-Archer Webseite, aus Katalogen stammen oder einer Websuche entspringen. Grün hinterlegte Zeilen deuten auf Modelle aus dem 2015er Katalog hin. Alle (bis auf Trike-spezifische Naben haben Rotationsschaltung. Zeilen in weiß werden nicht länger gelistet.

Model codes for hubs made in 1991 and later follow the pattern X-RD5, where the initial letter indicates the type of hub, R indicates rear, D a drum brake and 5 the number of gears. Model Features Documentation X-RC4 coaster brake. Specifications X-RD4 drum brake. Specifications X-RF4 no brake. Specifications X-RK4 disk brake. Specifications QS-RC5 Gearbox for quadricycle or tricycle. Has reverse gear, pullchain, coaster brake. Similar to TS-RC5 Installation QS-RC5 (W) Gearbox for tricycle. Has reverse gear, pullchain shifting No technical information RX-RC5 Coaster brake Installation RX-RD5 Drum brake Installation Parts list RX-RF5 Freewheeling, no brake Installation Parts list RX-RK5 Disk brake fitting Installation Parts list RXL-RD5 Large-diameter drum brake Installation Parts list S5C(W) Coaster brake, steel shell Installation, parts list S-RC5(W) Coaster brake, aluminum alloy shell Installation, parts list S-RC5(W)(N) Coaster brake, aluminum alloy shell, 9-spline driver Like S-R5C(W) S-RF5(W) Aluminum shell, freewheeling Installation Parts list for drum-brake model S-RF5(W)(N) Aluminum shell, freewheeling, 9-spline driver

Installation Parts list for drum-brake model TS-RC5 Gearbox for tricycle. Pullchain, coaster brake. Similar to QS-RC5 Installation TS-RF5 Gearbox for tricycle. Pullchain, freewheeling, no reverse gear. Installation XL-RD5(W) Aluminum shell, 90 mm drum brake Installation, parts list, exploded drawing. X-RC5(W) Aluminum shell, coaster brake, large flanges Installation, parts list X-RD5(W) Aluminum shell, 70 mm drum brake

Installation, parts list X-RF5(W) Large flanges, aluminum shell, freewheeling Installation Parts list for drum-brake model X-RK5(W) Large flanges, aluminum shell, disk-brake fitting

Installation Parts list for drum-brake model X-RK5(W)(N) Large flanges, aluminum shell, disk-brake fitting. 9-spline driver

Installation Parts list for drum-brake model

Designänderungen 1991 bis 2009

Now we move back earlier in time -- 1991-2009 hubs had ratios as in the table below: Ratio .667 .789 1.000 1.267 1.500 Step 18.4% 26.7% 26.7% 18.4%

The 1991-2009 hubs were never very common, are no longer sold and can be tricky or impossible to repair, due to parts un-availability. But who knows, you might have a couple of these lying around so you can cannibalize and keep one going.

The first of these hubs was the "5-Star" (5-Speed Sturmey-Archer), introduced in 1991. The 5-Star had cantilevered planet-gear axles, that is, the axles were supported at only one end, a Bad Idea. These hubs were shifted by dual pullchains: the one on the right for high, middle and low, and the one on the left for a wider and narrower range.

"Sprinter" hubs, introduced in 1993, had single-cable control and a sturdier planet cage.

Later versions of single-cable 5-speed hubs, sometimes called the Summit series, included a patented "ball locking" mechanism for the sun gears. Some of these hubs continued to be made, or sold out of remaining inventory, until SunRace/Sturmey Archer rolled out a new wide-range series of 5-speed hubs in 2009. The hub really needed 7mm or more of cable travel for the 1-2 and 4-5 shifts, but the plastic trigger shifter provided with these hubs provides only 6.5mm of travel for these shifts. The ball-locking mechanism was reportedly unreliable in the 7-speed hubs. Please also see comments on the 7-speed ball-locking hubs below, which probably also apply to the 5-speed hubs.

These hubs were supplied with an aluminum alloy shell, unless steel is indicated in the table below.

The hubs are listed in order of the year they were introduced. Model Year Features Documentation 5 Star 1991 Two cables: unreliable, cantilevered pinion pins Technical information Parts list 5 Star Elite w/drum brake 1991 Two cables: unreliable, cantilevered pinion pins Technical information Parts list Sprinter 1993 Single cable Technical information Another source Parts list Sprinter Elite AT5 w/drum brake 1993 Single cable Parts list Sprinter S5C coaster 1994 Single cable

Technical information Parts list SAB-5 Steelite w/drum brake 1998 Single cable Parts list AB5, w/drum brake 1999 Single cable, ball locking, steel shell, 90mm brake. Still available after Taiwan move. Parts list Summit S5 1999 Single cable, ball locking, freewheeling, steel shell, available after Taiwan move, reported on Tony Hadland's site Like X-RD5. Summit S5C 1999? Single cable, ball locking, coaster brake, steel shell. Available after Taiwan move, reported on Tony Hadland's site No information found Summit X-RC5 1999 Single cable, ball locking, coaster brake. Available after Taiwan move, reported on Tony Hadland's site No information found Summit X-RD5 1999 Single cable, ball locking, drum brake. Technical information Another source, also with specs Summit X-RF5 1999 Single cable, ball locking, freewheeling, reported on Tony Hadland's site Like X-RD5. Summit X-RK5 1999? Single cable, ball locking, freewheeling, disc brake fitting. I'm not sure this model ever actually was produced. Like X-RD5.

1939-1990

Now we go even deeper into the past. The FM medium-ratio four speed hub was introduced in 1939, and the FW wide-ratio four-speed hub, in 1945. It had all but the top gear shown in the table in the previous section. Additional four-speed hubs were added in the late 1940s. In 1967, Sturmey-Archer began making the S5 hub, which offered all 5 gears and was an easy upgrade from the FW. Ratio .667 .789 1.000 1.267 1.500 Step 18.4% 26.7% 26.7% 18.4%

This site now hosts Sutherland's Handbook of Coaster Brake and Internal Gear Hubs, with excellent rebuilding information on most of the hubs in this series. Boldfaced items in the table below are on this site. Other information linked below is mostly from the Sturmey-Archer Heritage site and Tony Hadland's Web site.

The hubs in the table below are listed in order of the year they were introduced.

Rebuilding information from Sutherland's Handbook More information from Sheldon Model Year Features Documentation FM 1939 Close-ratio, rare Rebuilding information Parts list FW 1945 Four speeds, single cable Technical information Rebuilding information Parts list and exploded drawing with annotations AF 1946 Same as the FC Rebuilding information Parts list FC 1946 Close-ratio, rare Rebuilding information Parts list FG 1946 Like the FW, with Dynohub generator Technical information Parts list and exploded drawing FB 1949 Like the FW, with drum brake Parts list and exploded drawing S5 1966 Two cables, bellcrank on left Technical information Another source Parts list and exploded drawing More information from Sheldon S5.1 1977 Indicator spindle, pullchain both sides. Unreliable. Technical Information Parts list and exploded drawing More information from Sheldon S5/2, S5/2A, 1983 Indicator spindle, pullchain both sides. Also sold with aluminum shell as 5-Speed Alloy. Technical information Another source Parts list and exploded drawing More information from Sheldon AT5 1985 Drum brake. Indicator spindle, pullchain both sides. Parts list S5/2 II 1988 Axle modification. Indicator spindles changed. Technical information

Über die FW und S5

The FW four-speed hub used the wide-range sun-gear setting to provide only a "super low" gear. The shift from normal "low" to "super low" ("2" to "1") required a very strong pull on the gear cable to overcome the spring that controlled the sun gears. This hub used a two-part indicator spindle whose adjustment is described here.

The right side of this hub was identical to that of the AW hub, and the internals would fit into an AW shell. The planet cage and axle assemblies were different.

Generator and drum-brake versions followed in 1946 and 1949. They used a narrower planet cage and plunger-type low-gear pawls, to make room for the generator or brake.

Many cyclists converted the FW four-speed into a five-speed by adding a separate shifter for the sun gears. This was a hot ticket for a club-riding bicycle, back around 1950.

Sturmey-Archer also made other four-speed hubs with narrower ratios, to appeal to club cyclists and racers. You may read more about them on Tony Hadland's site and the Sturmey-Archer Heritage site, and in John Allen's documentation of gear ratios. John Forester's writeup about these hubs is now on this site.

The S5 5-speed hub worked like the converted FW hubs. Most of the internal parts were the same as for the FW, and the right side including the gear ring remained the same as for the AW. The S5 used two cables:

- The normal one on the right side worked as a normal 3-speed.

- The second cable on the left side shifted the sun pinions.

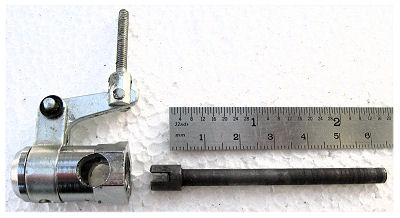

The original 5-speed hubs used a bellcrank to push a rod inward to accomplish the sun-pinion shift.

The S5 was sold with three different types of bellcrank, reminiscent of the story of the Three Little Pigs. One type of bellcrank was made partly of plastic and failed quickly. A second type used a flimsy steel stamping, and bent easily. Only the sturdy, forged type with internal threads is reliable, but it is rare. I've had some success modifying Shimano bellcranks to fit. I did this by re-threading them to fit the Sturmey-Archer axle. Taps for this purpose are not readily available, so I made a tap out of an old axle.

The bellcrank had to face forward to connect with the cable, and so it could not be tightened to secure the axle in the dropout. A separate axle nut was needed. The bellcrank works best with a 6 1/4" axle. Grinding a recess in the side of the axle to secure the Shimano bellcrank's grub screw and drilling out that bellcrank to fit over the threads also might work. A bellcrank could be fabricated from the flared axle nut used with a Sturmey-Archer indicator spindle. With the bellcrank, the S5 was reliable and a fine choice for urban cycling. I [John Allen] still use an S5 hub, and you may be lucky enough to find one in an old wheel.

5 3/4" and 6" axles also were sold, but they are not long enough when used with the good bellcrank if there is any spacing washer under the left-side locknut. The 6" axle is longer only on the right side. A pushrod for the good bellcrank can be made from a ten-penny nail by cutting it to 2 15/16" long (or 2 11/16" for the shorter axles) and grinding down its head to fit inside the bellcrank.

Unlike recent hubs -- and like the old version of the AW 3-speed -- all of the 4-speed and 5-speed hubs in this series could "walk" out of high gear position into the intermediate (neutral) gear during a hard sprint -- see comments by Jobst Brandt. The more common cause of gear disengagement, though, was misadjustment of a shifter cable. With these hubs, there is a "neutral" gear between engagement of the sun gears as well as the one between middle and top ranges.

Fünffach Naben mit Zwei Zügen

The weak point of the 2-cable 5-speed hubs was the shift control units. The S5 required a taut cable to prevent the primary sun gear from disengaging from the axle in first gear. Sturmey-Archer went through a number of top-tube mounted shift levers, which were never very satisfactory mechanically. The left-side cable needed to be very carefully adjusted, and the actual mechanics of the click stops in the two-lever controls were too weak, so they were quite unreliable, even though there was no real problem with the hubs.

Also, unsophisticated cyclists had trouble mastering the shift sequence of the two separate levers. It could also be confusing that the S5 must be pedaled forward at more than first-gear speed when shifting from second to first.

Later 2-cable versions reversed the spring loading on the sun gears, and used a conventional indicator spindle/chain to shift the sun pinions. The first of these, the S5/1, would not reliably stay in gear. The last version of the S5 hub, the S5/2 II, was also sold as the S5 Alloy and with a drum brake as the AT5. It was reliable, and it would shift into all gears without pedaling forward, but the problem with the shifters remained.

Sturmey-Archer eventually made a large and very complicated single-trigger control that would operate the two cables, but it was also very temperamental and required a lot of force to operate. The best control arrangement for a 2-cable 5-speed hub is a standard 3-speed trigger for the right cable, and a friction-type derailer shift lever for the left cable. The use of the friction shifter on the left gets around the problem of critical adjustment of the left cable, since you just pull it until it stops.

[I use a trigger on the left, in the 2nd and 3rd gear positions. Its latching in the 2nd gear position holds the cable taut. The cable does need adjusting occasionally. I have used the original S5, and the S5/2 II, each for years, and had no problems with them except when the cable is misadjusted -- John Allen.]

Newer 5-speeds (described earlier in this article) use a single cable, and rather different internals.

Sieben Gänge

In 1997, Sturmey-Archer introduced three models of "Sprinter 7" 7-speed hubs -- brakeless, or with a drum brake or coaster brake. These were the first production Sturmey-Archer hubs with rotary shifting. They are relatively rare. Ratios were as follows: Ratio .600 .690 .804 1.000 1.243 1.450 1.667 Step 14.9% 16.6% 24.3% 24.3% 16.6% 14.9%

Information below is from the Sturmey-Archer Heritage site and Tony Hadland's Web site.

7-speed hubs were also produced in the "Summit" series, with a ball locking mechanism for the sun gears, under different model numbers, in 1999 and 2000. These hubs did not remain in production after Sturmey-Archer's move to Taiwan.

These hubs were installed on some Moulton bicycles, and may have been reliable enough with the low-torque conditions of a small-wheel bicycle, but a cyclist who used them for heavier service in a hilly city reports:

The weak point of these hubs was the sun gears, and the system of fixing them to the axle. The original system used a sliding key, similar to that used in the Sachs/SRAM hubs, but one-sided (projecting from one side of the axle instead of both). This key and the notches that it engaged were prone to having their corners rounded off and then not yielding proper engagement. The next system used small ball bearings that would retract or protrude from the axle and engage the sun gears. Unfortunately, under extreme torque the sun gears tended to override the balls, either becoming permanently engaged with the axle or shattering. Back to the drawing board, eh? Model Features Documentation S7 Steel shell, no brake Technical information Another source Parts list AT7/ Sprinter 7 Elite Aluminum shell, drum brake Technical information Another source Parts list S7C Aluminum shell, coaster brake Technical information Another source Parts list Summit S7 Aluminum shell, no brake, ball locking Like X-RD7 Summit S7C Aluminum shell, coaster brake, ball locking Like X-RD7 Summit X-RD7 Aluminum shell, drum brake, ball locking

Technical information

Siehe auch

The Sturmey-Archer official site has some information on newer hubs not included here. The Sturmey-Archer Heritage Web site has a wealth of historical and technical information, very helpful for older hubs not covered on this site. Tony Hadland's Web site includes an exploded drawing and parts list for nearly every Sturmey-Archer hub ever made up through the 1980s, as well as rebuilding information for many older hubs. The service manuals include general information (such as how to replace pawls) not covered in the rebuilding information for individual hubs.

Rebuilding instruction for several hubs on Jane Thomas's site Sturmey-Archer 1951 Service Manual on the Sturmey-Archer Heritage site. Sturmey-Archer 1951 Service Manual on Vancouver Van Touring site 1956 service manual and 1902-2001 information on Tony Hadland's site Sturmey-Archer logo Official Site old Sturmey-Archer logo Heritage site Three-Speed Parts from Harris Cyclery John Forester on five-speed hub gears English Three Speeds, Care and Feeding Internal-Gear Hubs Sturmey-Archer Hubs, General Information Sturmey-Archer 1902-1952 Sturmey-Archer 1935-38 Catalogues Evolution of the Raleigh Sports Sheldon's Moulton MKIII Sheldon's Moulton MK3 with S5 hub and hybrid gearing John Allen's spreadsheets of internal-hub gear ratios Martin Hanczyc's roadster pages. Tony Hadland's Sturmey-Archer Pages including the 1956 master catalogue and a Web page with technical documentation on some of these hubs, among others. Hubstripping web site Retro Raleighs SW Hubs by Brian Hayes Jane Thomas's site with Sturmey-Archer service manuals. Menotomy Vintage Bicycles Chat forum on English bikes.

Quelle

Dieser Artikel basiert auf dem Artikel Servicing Sturmey-Archer 4- 5- and 7- Speed Hubs von der Website Sheldon Browns. Originalautor des Artikels ist Sheldon Brown.